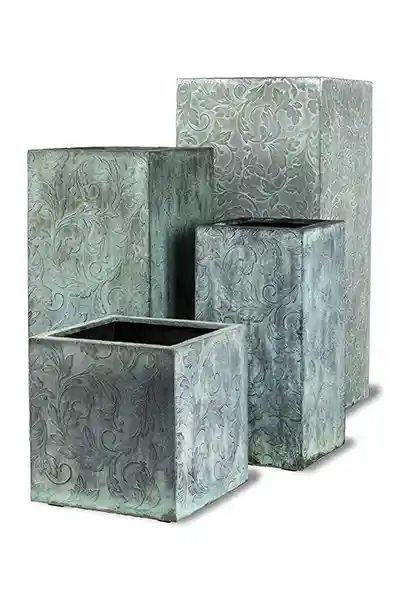

Capital Garden Products’ planters are created in farm buildings in the depths of Sussex. These action photography shots were taken to add to their latest catalogue. They show the various stages of creating their fibreglass planters, from moulding to the ageing techniques to make them so convincing.

Original Master Made From Metal

When manufacturing a lead or metal reproduction planter, a mould is made taken from a master made in the original material. This ensures that all the natural imperfections are carried through for an accurate representation.

Authentic Finishes

Capital Garden’s production techniques are being continually researched and developed to produce new finishes to replicate a multitude of materials that are indistinguishable from the real thing. Their list of finishes includes; antique brass, beaten copper, old penny bronze, terracotta, lead, aluminium, stone, concrete, limed wood, zinc and rust.

Creating Olive Trees

The olive trees start with real dead trees, which are then planted with the fake leaves. They are then ‘planted’ by fixing them into their pots ready to be transported all around the world.

Window Box Installation

The last three photographs show window boxes being installed – before and after. The brown plants are the real ones. The bushy green plants are the realistic fake box plants. The London house looks much smarter with these replacement window boxes.

Benefits of Being Lightweight

Most rooftops and balconies are unable to take the weight of a gigantic pot filled with compost. Capital’s products are ideal for this situation. They are also weather proof so no cracked pots and no falling leaves either.

See more photos and designs for Capital Garden Products

Cut out planters photographs

Planters catalogue design

Planters folding leaflet design

Plants photographs

Plants catalogue design

Visit Capital Garden Products website

Colin Walton at WaltonCreative.com

Colin Walton at WaltonCreative.com